Protect your people and facilities with effective fire-resistance

Choosing the right fire-resistant fluid can be a complex decision and involves balancing product performance, cost and regulatory requirements. Ongoing changes in industry standards can also influence the selection process.

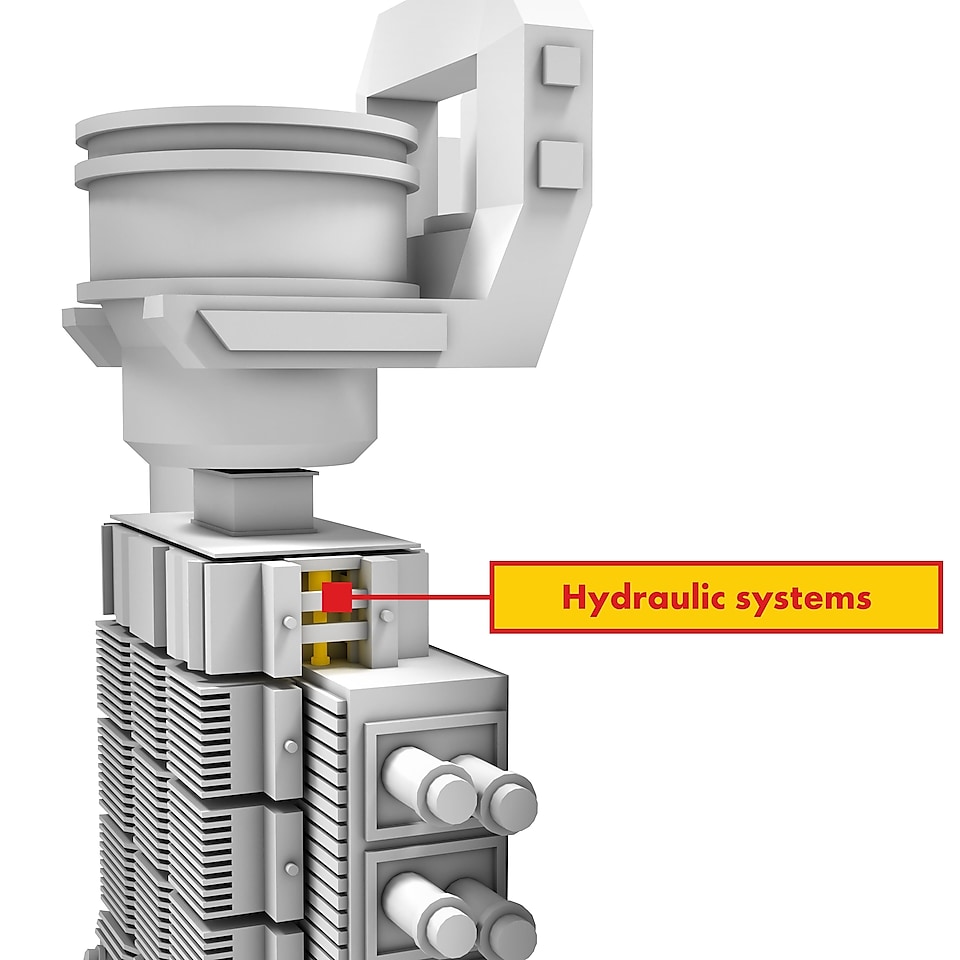

Drive system efficiency in your hydraulic equipment with excellent component protection – all while reducing the risk of fluid ignition to improve the safety and productivity of your facilities.

Our range of fire-resistant hydraulic fluids provide enhanced protection to reduce the risk of ignition and prevent fire hazards in your operations.